Menu

How To Build A Pallet Step 5

Please provide a rating, it takes seconds and helps us to keep this resource free for all to use

In logistics, it is possible to build a pallet with the carton placed in one of six different positions in relation to the Pallet that you are using to transport your goods. In this guide we cover Step 5 for building an Optimal Pallet Build Configuration as illustrated and calculated on the advanced Pallet Calculator

Carton to Pallet Position: How To Build A Pallet Step 5

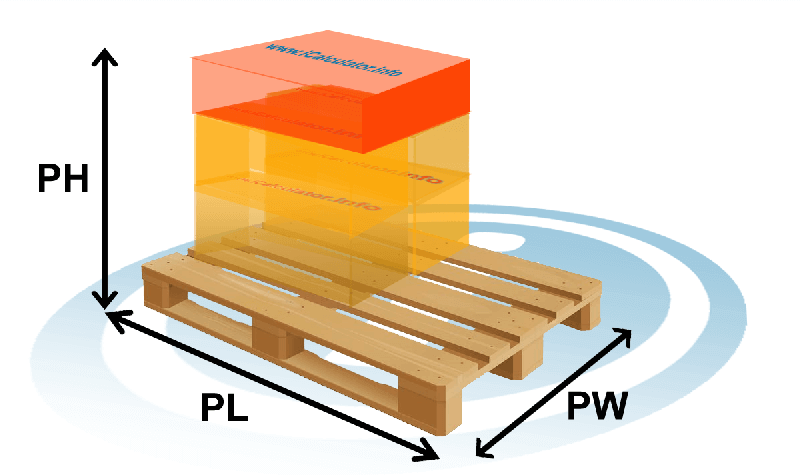

The image below illustrates how the pallet should look at step 5 of the pallet build.

Our pallet ( in how to build a pallet step 5 ) is built by placing one carton at a time, aligning the carton to the pallet as follows:

In step 5, we can see that in this example, we can no longer fit any of the same size cartons onto the pallet in their original position. This does not mean we cannot add more cartons, it simply means we need to understand the remaining space (dimensions, area and volume) remaining on the pallet. The image illustrates the 'void' above the stacked cartons. This is the space that exists between the highest point of the stacked cartons and the highest point at which the pallet can be stacked. Pallet stack heights vary depending on whether you are using road, rail, sea (ocean) or air freight transport services and, if you use a third party logistics company, they will have their own caveats published for pallet build heights. If you built a pallet beyond the specified height, it will be treated a s'out of gauge' and will typically attract additional transportation costs or, in certain cases, not move at all. If you have a large product which is 'out of gauge', you should liaise with your logistics provider before attempting to move it through the supply chain, failing to do so will only result in delays, unhappy customers and increased transportation costs.

As the pallet builds, the volume of the pallet is slowly filled. Unless you are very lucky and the dimensions work out just right, you will typically be left with space within the pallet build configuration. This can be filled with additional product by turning the cartons through anyone of the 6 positions that a carton can be placed on a pallet. Using this technique, you can manually optimise your pallet build and get the most cartons/boxes onto your pallet. Alternatively you can use the advanced Pallet Calculator which will automatically calculate the optimal load configuration for a pallet for you.

Notes on this Pallet Build Guide

- In this pallet build guide which is provided in support of the Advanced Pallet Build Calculator, we have assumed that the boxes/cartons can be stacked in any direction (so they are any way up). In order to do this you must ensure that the quality of the product is not compromised and that the carton containing the products is strong enough in all positions to sustain the weight of additional cartons stacked on top of it. Note that not all boxes and cartons are designed to be stacked and support weight in all directions.

- In logistics, the term 'building a pallet' refers to the process of placing cartons (also called boxes, products, goods etc.) onto a pallet. The pallet is typically wooden though plastic and metal pallets are used in certain industries for specific goods. Cartons are placed according to the properties and constraints of the goods within the carton and the cartons properties. Some cartons can only be placed one way up, other can be placed in any direction. Cartons which contain sensitive products and/or high value/high quality goods should be clearly marked with directional arrows to ensure that the individual who builds the pallet is clear on the limitations of the carton he/she is handling.

- Ideally, where applicable, all cartons which have to be stacked in a certain direction should have 'up arrows' and indicate 'non-stackable' if they are not suitable for having additional products stacked on top of them.

How to optimise your pallet build

An optimal pallet build identifies all available voids surrounding the goods and calculates the space available for stacking additional products / cartons etc. The Advanced Pallet Calculator does this automatically by identifying the three key voids which exist when cartons/boxes/product is placed onto a pallet. The images below (which can be clicked to be viewed full screen) highlight the locations of those voids. The advanced pallet calculator results will identify these voids, their properties (width, length, height and cubic area) and, where feasible, place cartons into these spaces (depending on any way up / stackable properties).

| Click on the images below to see a larger picture and additional information. | ||

Pallet Void 1 |  Pallet Void 2 |  Pallet Void 3 |

Pallet Build Configuration Options

Pallets can be built by placing boxes/cartons onto a pallet in one of six different configurations. The links below highlight the different pallet build configurations that are possible.

- Pallet Optimisation 4

- Pallet Optimisation 5

- Pallet Optimisation 6

- Pallet Optimisation 6

- Pallet Optimisation 8

- Pallet Optimisation 9

- Pallet Optimisation 10

- Pallet Optimisation 11

- Pallet Optimisation 12

- Build Configeration One

- Build Configeration Two

- Build Configeration Three

- Build Configeration Four

- Build Configeration Five

- Build Configeration Six