Menu

Advanced Pallet Calculator

Please provide a rating, it takes seconds and helps us to keep this resource free for all to use

The advanced pallet calculator will automatically calculate volumetric weight, maximum carton load, pallet load efficiency and provide other logistics information. This tool is more advanced than our basic pallet calculator as it allows for building cartons anyway up and optimising carton positions to ensure maximum use of pallet space.

- Enter carton outer dims, weight and total number of cartons

- Select Pallet type to be used for the pallet calculation

- Calculate or select advanced to alter default settings

Please provide a rating, it takes seconds and helps us to keep this resource free for all to use

Advanced Pallet Calculations

The information provided by the Advanced Pallet Calculator is particularly useful for maximising pallet builds by buliding with goods positioned any way up. This reduces distribution costs when sending export freight through a Freight Forwarder though it can be a balance of cost versus quality.

iCalculator Logistics Calculators are regularly updated to include new features and facilities to support the logistics industry. Whether you are trying to calculate the volumetric weight of an item of trying to work out how many items you can fit into a 40ft container, iCalculator has the right tool for you.

All the logistics calculators featured on this site are free to use. The calculators are designed to be used online, if you do experience difficulties or your looking for a calculator which isn't featured, please contact us. We are always looking for new projects and ideas so we are happy to receive your feedback and wish lists.

How to calculate pallet requirement

A step by step guide on how to use the pallet calculator

- Select unit of measurement (mm = Millimetres, in = inches)

- Enter carton width

- Enter carton length

- Enter carton height

- Enter total number of planned cartons

- Select the type of pallet that you will be using

The pallet calculator will now automatically calculate the logistics metrics for you pallet build including volumetric weight

Advanced Pallet Calculator

The Pallet Calculator uses logistics industry standard caveats and metrics as default. The advanced calculator allows you to alter the standard logistics metrics for use of bespoke pallet build / vehicle use.

Advanced Calculator features include:

- Overhang Depending on your product type, it's packaging and the quality control program in use, you may want to build your pallets using an overhand. Some carriers will not accept pallets with overhang, so it is worth discussing with your logistics manager before building pallets with overhang. If building with overhang is viable in your supply chain network and you can retain the quality of product through the supply chain then it is worth building your pallets with an overhang as this can save considerable costs on transportation, particularly if your goods are relatively light in weight.

- Stackable Ensuring that your goods can be stacked will provide you with the most cost-effective means of moving your freight. Non stackable freight is costly as the space above the goods is lost. Cost metrics aside, non-stackable freight increases carbon expenditure on the movement of goods. Overall, the logistics industry does not like non stackable goods.

- Max Pallet Height: This height caveat is based on freight forwarding height build restriction for lower deck aircraft pallet build. You can plan for higher if using an industry leading freight forwarder. Pallets that are travelling by road and sea can be built higher but you should consider the health and safety aspects of building tall pallets.

- Any Way Up: ↑↑ Most goods are packed to be transported in their vertical position as packed; that is 'top up'. This is typically identified by stickers or markings with 2 arrows facing up ( ↑↑). Only select Yes if your goods can be stacked in any configuration. Note: Ensure both the goods and the packaging are capable of this handling!

- Pallet Weight: This weight is the standard weight of an average wooden pallet. This weight forms part of the consideration for freight movement.

Pallet Build Configuration Options

Pallets can be built by placing boxes/cartons onto a pallet in one of six different configurations. The links below highlight the different pallet build configurations that are possible.

- Pallet Optimisation 4

- Pallet Optimisation 5

- Pallet Optimisation 6

- Pallet Optimisation 6

- Pallet Optimisation 8

- Pallet Optimisation 9

- Pallet Optimisation 10

- Pallet Optimisation 11

- Pallet Optimisation 12

- Build Configeration One

- Build Configeration Two

- Build Configeration Three

- Build Configeration Four

- Build Configeration Five

- Build Configeration Six

How to build a pallet

A skilled warehouse worker can build a pallet effectively with very little thought and will typically achieve good effective build rates but the best approach to pallet building is to first produce a pallet configuration using the pallet calculator. This allows the pallet builder to understand how the pallet can be built when boxes/cartons are placed in any one of their 6 configuration options. Having a skilled warehouse staff is excellent, but they are human and as such can have good and bad days. Human error is fine as long as you plan for it. By using a pallet configuration calculation your pallet builder can use it either as a detailed plan for building the pallet or simply as a quick reference to ensure their approach to the pallet build is optimal. Either way, the pallet calculator provides a great reference that allows you to optimise your supply chain and keep your transportation costs down to a minimum.

- How to build a pallet step 1

- How to build a pallet step 2

- How to build a pallet step 3

- How to build a pallet step 4

- How to build a pallet step 5

- How to build a pallet step 6

- How to build a pallet step 7

- How to build a pallet step 8

- How to build a pallet step 9

- How to build a pallet step 10

- How to build a pallet step 11

- How to build a pallet step 12

How to optimise your pallet build

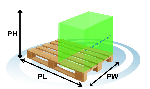

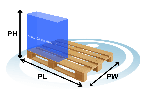

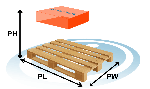

An optimal pallet build identifies all available voids surrounding the goods and calculates the space available for stacking additional products / cartons etc. The Advanced Pallet Calculator does this automatically by identifying the three key voids which exist when cartons/boxes/product is placed onto a pallet. The images below (which can be clicked to be viewed full screen) highlight the locations of those voids. The advanced pallet calculator results will identify these voids, their properties (width, length, height and cubic area) and, where feasible, place cartons into these spaces (depending on any way up / stackable properties).

| Click on the images below to see a larger picture and additional information. | ||

Pallet Void 1 |  Pallet Void 2 |  Pallet Void 3 |